The DNA ofEvery Component

Complete material genealogy from raw materials to finished products. Track, trace, and transform your manufacturing with OPUS MGL.

Trusted by Leaders in

The Cost of Poor Traceability

Industry-wide challenges that traceability solves

Manufacturers waste over $275B yearly on unnecessary product recalls

Global counterfeiting reached $4 trillion in 2023

Aerospace counterfeit part reports rose 142% between 2005-2008

Over 20% of road accidents caused by malfunctioning counterfeit components

Traceability isn't optional anymore — it's essential for survival.

Everything you need for complete visibility

From raw materials to finished products, OPUS MGL gives you unprecedented control over your manufacturing process.

Complete Genealogy

Track every component from raw material to finished product. Know the complete ancestry of every part in your production.

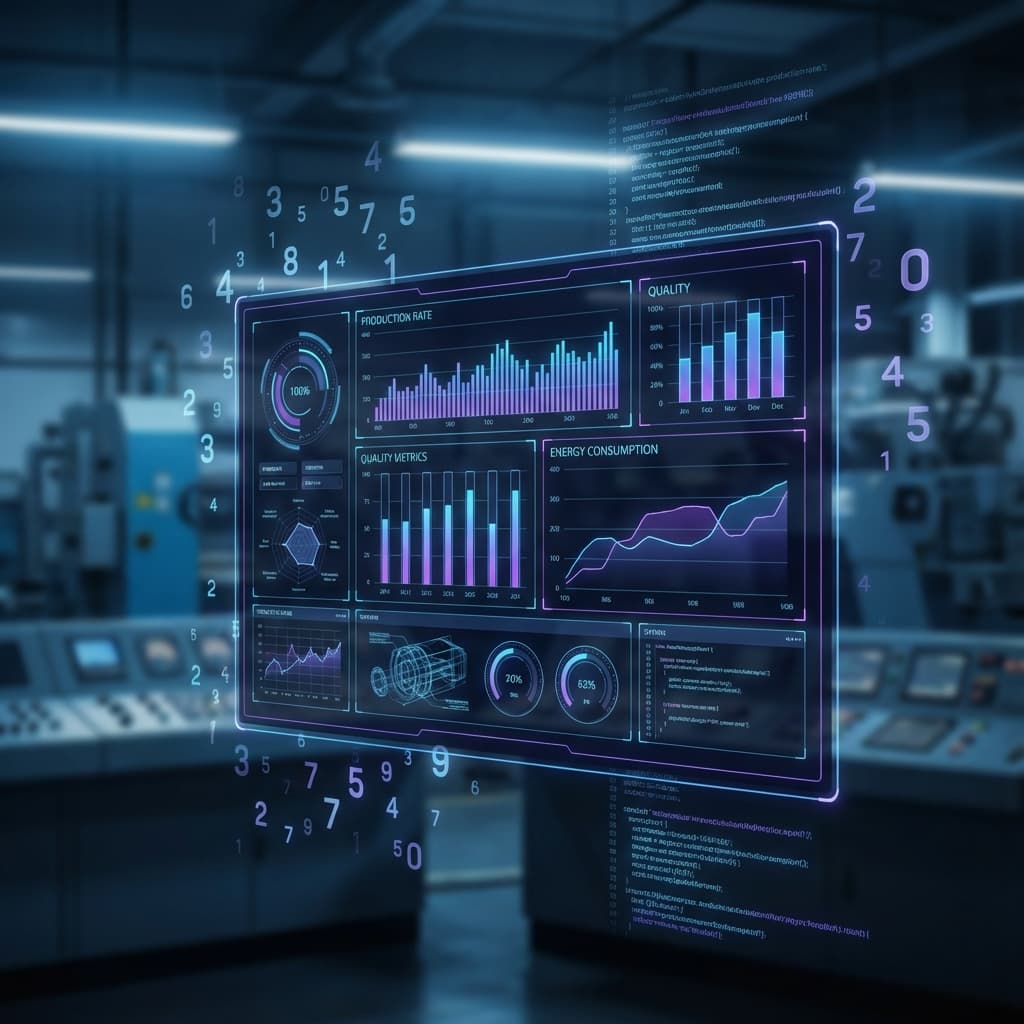

Real-time Analytics

Live OEE metrics, production dashboards, and predictive insights. Make data-driven decisions in milliseconds.

Quality Assurance

Integrated Andon systems, defect tracking, and automated quality gates. Zero defects, zero recalls.

Instant Traceability

Query any component's complete history in under 50ms. From supplier to customer, every step documented.

Multi-layer Tracking

Track assemblies, sub-assemblies, and individual components. Unlimited nesting levels for complex products.

Global Operations

Multi-plant, multi-language support. Unified visibility across your entire manufacturing network.

Smart Alerts

AI-powered anomaly detection and proactive notifications. Know about issues before they become problems.

Compliance Ready

Built-in IATF 16949, ISO 9001, and FDA 21 CFR Part 11 compliance. Audit-ready documentation always.

From raw material to complete genealogy

Five simple steps to achieve complete traceability across your entire manufacturing process.

Material Intake

Scan and register incoming materials with supplier data, batch numbers, and quality certificates.

Process Tracking

Every operation recorded: timestamps, operators, machine parameters, and quality measurements.

Assembly Genealogy

Link components to assemblies, track parent-child relationships across unlimited levels.

Real-time Analytics

Instant visibility into production status, quality metrics, and performance indicators.

Complete Traceability

Query any product's complete history in milliseconds. From supplier to customer.

Visualize the complete ancestry

Every product has a story. OPUS MGL traces it from raw materials to final assembly.

Built for precision industries

From automotive to aerospace, medical to electronics. OPUS MGL adapts to your industry's unique requirements.

Automotive Manufacturing

Track every component from supplier to final assembly. Designed to support IATF 16949 traceability requirements.

Challenges We Address

- Complex multi-tier supply chains

- Strict regulatory requirements

- Recall management

Key Benefits

- Faster recall response capability

- End-to-end component traceability

- Streamlined compliance reporting

Real capabilities, no marketing fluff

These are features we've actually implemented and tested. No inflated metrics, no fake testimonials.

Serial-Level Tracking

Every component gets a unique identity. Track individual items, not just batches.

Parent-Child Relationships

Unlimited nesting levels. Assemblies within assemblies, all connected.

Complete History

Every operation, timestamp, and operator recorded. Full audit trail.

Quality Integration

Andon calls, quality checks, and defect tracking built-in.

Real-time OEE

Live equipment effectiveness metrics. Availability, performance, quality.

Multi-language

Turkish, English, German - ready for global operations.

Flexible deployment, your choice

Whether you need cloud convenience or on-premise control, we adapt to your requirements.

Cloud

Hosted solution, we handle everything

- Quick setup - days not weeks

- Automatic updates & backups

- Scalable infrastructure

- No IT overhead

- Multi-language support (TR/EN/DE)

On-Premise

Full control, your infrastructure

- Complete data sovereignty

- Air-gapped network support

- Custom integrations

- Your security policies

- Dedicated support

Let's talk about your needs

Every manufacturing operation is unique. Tell us about your traceability requirements and we'll create a tailored solution.

No commitment • Free consultation • Response within 24h